Our Current Print Technologies

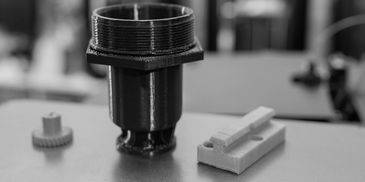

FDM (Fused Deposition Modeling)

FDM (Fused Deposition Modeling)

FDM (Fused Deposition Modeling)

Ideal for rapid prototyping and small-batch production. Widest material availability with high affordability. In FDM, a continuous filament of thermoplastic is heated and extruded through a nozzle, depositing it layer by layer onto a build platform to form a 3D object.

SLA (Stereolithography)

FDM (Fused Deposition Modeling)

FDM (Fused Deposition Modeling)

Ideal for extremely detailed parts for either prototyping or final production. SLA printing works by using an ultraviolet (UV) laser to selectively solidify a liquid photopolymer resin layer by layer to form a 3D object

SLS (Selective Laser Sintering)

FDM (Fused Deposition Modeling)

SLS (Selective Laser Sintering)

Ideal for final batch production. Selective Laser Sintering (SLS) uses a laser to fuse powdered material, typically polymers, layer by layer into a solid object.

PRINT MATERIAL OFFERINGS

PLA (FDM)

Prototyping Resins (SLA)

Prototyping Resins (SLA)

Our go to material for everyday prototyping, fit checks, and understanding design feel. Affordable, quicker to print, and great details.

Prototyping Resins (SLA)

Prototyping Resins (SLA)

Prototyping Resins (SLA)

Our go to material for everyday prototyping. Affordable, quicker to print, and great details.

NYLON - PA12 (SLS)

Prototyping Resins (SLA)

NYLON - PA12 (SLS)

Best for high detail and great dimensional accuracy. Go-to material for SLS 3D printing, it is ideal for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability.

PETG (FDM)

Tough Engineering Resins (SLA)

NYLON - PA12 (SLS)

Perfect when higher rigidity, toughness, or strength is required from the part.

Tough Engineering Resins (SLA)

Tough Engineering Resins (SLA)

Tough Engineering Resins (SLA)

Perfect when higher rigidity, toughness, or strength is required from the part.

NYLON - PA11 (SLS)

Tough Engineering Resins (SLA)

Tough Engineering Resins (SLA)

Strong and highly ductile bio-based material. Ideal for robust biocompatible parts, functional prototyping, and producing custom or low volume end-use parts that need to bend or take impact.

Nylon - Carbon Fiber (FDM)

Silicone & Flexible Resins (SLA)

Silicone & Flexible Resins (SLA)

Perfect fusion of stiffness, flexibility, and heat resistance.

Silicone & Flexible Resins (SLA)

Silicone & Flexible Resins (SLA)

Silicone & Flexible Resins (SLA)

Ideal for elastomeric applications (O rings, bushings, bellows etc.)

TPU (SLS)

Silicone & Flexible Resins (SLA)

Nylon - Glass Fiber (FDM)

Tough elastomer with high elongation at break and superior tear strength for flexible, resilient, and skin-safe prototypes and end-use parts.

Nylon - Glass Fiber (FDM)

High Temperature Resins (SLA)

Nylon - Glass Fiber (FDM)

Perfect fusion of stiffness, flexibility, and heat resistance. Ideal for low friction applications.

High Temperature Resins (SLA)

High Temperature Resins (SLA)

High Temperature Resins (SLA)

The name says it all. This resin is capable of withstanding high heat with a current Heat Deflection Temp. of 460F

NYLON - PA11 CF (SLS)

High Temperature Resins (SLA)

High Temperature Resins (SLA)

Carbon fiber-filled Nylon PA-11 material, perfect for applications that require both superior stiffness and strength. Printed parts are lightweight, rigid and will remain structurally and thermally stable, able to sustain repeated impact.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.